Global competition in the industry more and more intense, since ten years ago for the first time since the concept of smart grid, the word "smart" has become synonymous with innovation, in order to adapt to the new technology rapid development and new product life cycle shorten constantly, people need more and more striking marketing market behavior, so the concept of intelligent to describe characters and product more and more, such as intelligent factory, smart meters, smart phones, intelligent building, intelligent toys, smart home, intelligent and smart society, makes our modern people very panic and tired, Will an intelligent human replace our modern human? Society or in accordance with the law of development of it, however, go forward, when we are continuing to search for "smart", the mystery of science and technology revolution, the industrial revolution, the industrial revolution calls for more and more high, Jeremy rifkin prophecy "third industrial revolution, Germany launched" industrial 4.0 "now many colleagues called" the fourth industrial revolution ", the "new industrial revolution" is put forward. At a time when such seminars and summits are in full swing, the industrial revolution has become the biggest buzzword. Are these revolutions an opportunity or a challenge for China? Is China ready?

Every change to big to society, small enterprises and individuals to bring change, change towards the direction of the positive or negative direction development it all depends on whether people really know what is the driving force of these so-called "revolution", what is the cause of its produce. If people can really explore these depths and connotations and grasp the essence of the so-called "revolution", then we will not only know it, but also know why. In this paper, by analyzing the cause and basis of industry 4.0, the purpose of promoting industry 4.0 in Germany is determined. To understand its strategy and tactics. Try to draw some enlightenment to China's manufacturing industry.

Industry 4.0 is an industrial revolution led by modern manufacturing industry. At present, colleagues are talking about technological revolution, industrial revolution and industrial revolution, but what are the differences between these revolutions? What are the main features and symbols of various revolutions?

A simple explanation is needed. People often say that technology is the first productivity. Indeed, each time the industrial revolution came from technology revolution, in general, the first revolution of science and technology, human society and the scientific and technological achievements applied successfully in certain areas, to produce the industrial revolution. The rise of various industrial revolutions led to the industrial revolution. From this point of view to understand, we can more rationally to meet the current proposed all sorts of revolution, can follow the requirements of the revolution, at the same time develop controlled, effective and feasible strategies and countermeasures. What, then, is the greatest source of the revolutions that our society now faces? It's actually Internet technology. Internet technology has influenced our human society, for the development of the society plays a big role, this new technology is day and night to infiltrate all walks of life and promote corresponding technical revolution in all walks of life.

Such as the United States rifkin's third industrial revolution is, in fact, the Internet technology application in the field of new energy, produced the new energy revolution, the scattered distribution of new energy resources, local access and the combination of the Internet has a smart grid, and produced a third industrial revolution. As a result of these new areas of development, need a lot of new technology, new products, new engineering solutions, and the introduction of energy storage control technology, micro network technology, cloud technology, the Internet of things, new innovation ideas and methods, such as power management technology, formed the industrial revolution in the field of energy. So it's essentially a new industrial revolution combining new energy with the Internet. Its driving force is the application of Internet technology in the new energy field.

For example, industry 4.0, the so-called fourth industrial revolution related to this paper, what is its origin? What is the problem it's trying to solve? Why did Germany make industry 4.0 a central part of its science and technology development agenda?

It is reported that Germany's Siemens industrial group President Dr Ruth he worked in Chinese academy of engineering and academic report at the meeting, held by the state-owned assets supervision and administration commission of the state council "industrial 4.0" concept is that intelligent manufacturing as the leading factor, the fourth industrial revolution and revolutionary production methods. Smart factories will be a key feature of the future industrial system. In a smart factory, people, machines, and resources communicate and collaborate as naturally as in a social network. Produces intelligent products can understand oneself is made in detail, and how to use, can answer "which set of parameters is used to deal with me", "where should I delivered to" and so on. In smart factories, smart auxiliary systems will be liberated from routine tasks, enabling them to focus on innovative and value-added activities. Flexible working organizations can help workers integrate life and work better, and the needs of individual customers will be satisfied.

If the popular understanding, is the production manufacturing man-machine integration. In the future, manufacturing systems will no longer be dominated by humans alone. Instead, machines will be able to adapt to meet or even exceed people's expectations. The expert's description does paint a rosy picture for our automation peers, as if a disruptive industrial revolution had really come. People began to make "innovative" explorations again, and began to learn, research, summarize and improve the cognition process. Many prospective articles were published, which provided excellent references and Suggestions to the peers. New concepts such as smart factories, intelligent production, digital factories, smart factories, cyber-physicalsystems and so on have emerged. Whether the translation of "cyber-physicalsystem" into an information PhysicalSystem understands the true meaning of the "industry 4.0" strategy is debatable. The author also involved in the wave, and Germany's main formulate industrial enterprises and industry associations, 4.0 4.0 projects are engaged in industrial university, the institute has carried on the exchange, also visited some 4.0 research project is developing industry. Gradually understand why Germany will promote industry 4.0, what is the basis for Germany to promote industry 4.0, German industry

4.0 is a strategy or a revolution. The following experiences are obtained:

1.1 to 4.0 is the rapid development of science and technology to promote German industrial production mode change the product of Germany is the consensus of the world's focus on innovation, industrial product research and development of national science and technology, especially in the management of complicated manufacturing process, in the field of information technology has a high level of ability, in the embedded system and factory automation also has a professional technology, these factors laid a German in the manufacturing engineering industry leader. But when the Internet into the human history, how to make Germany as a new generation of industrial production technology supplier and dominate the market, make Germany under the precondition of the development of a new manufacturing to enhance the global competitiveness of it again. This paper reviews the development of manufacturing industry in Germany and makes a very incisive exposition. See below:

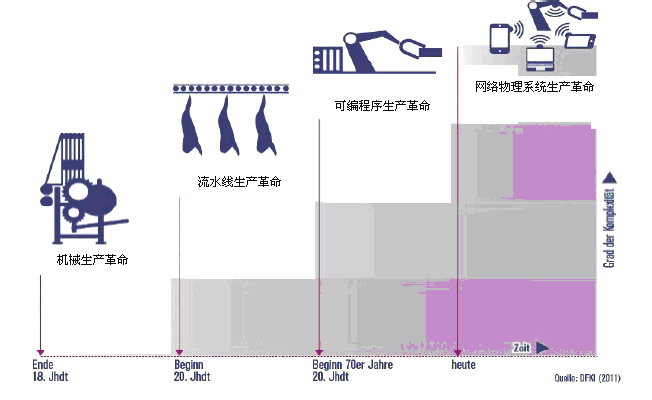

According to the definition of industrial 4.0, industrial development is obviously under the impetus of the science and technology innovation, so it was assumed that the first industrial revolution is the invention of the steam produced by the production of mechanization. We call it the mechanization of production, and the second industrial revolution was due to the invention of electricity and mass production, called the production line. The third industrial revolution resulted from the development of electronic technology and computers, which produced automatic production and manufacturing methods, making products richer and more functional. 4.0 strategy from the industrial analysis can be seen, the development of science and technology will inevitably enter the industry, and will have the greatest impact on industry is the change of production method, the change of production methods and promoted the industry changes, if we review a little bit about the industrial development, from textile industry, steel industry, automobile industry, chemical industry, electronics industry rising and development can prove it, so we can be no exaggeration to say that production way of change and innovation will be the industry and even the beginning of the industrial revolution. Nowadays, with the rapid development of science and technology, especially IT and Internet technology, which have penetrated into every aspect of human life, can these technologies be successfully applied to the manufacturing industry? This may be the first question that industry 4.0 designers consider. How to solve this problem must also follow two major principles :(1) the change of manufacturing methods must adapt to the development and future of the present manufacturing industry. (2) the application of any new technology must combine with the original production mode, is the inherit and carry forward the original manufacturing model, as technology of the original model for sedimentary and accumulation of recycling and breakthrough. Starting from this principle, industry 4.0 has formulated the correct positioning strategy and tactics.

4.0 1.2 industry is an industry technical transformation, is the industry change from mentioned above can be seen in the three times industrial development, due to the new science and technology successfully used in industry, transformational progress makes manufacturing mode, that is, from a single manufacturing, small workshops to mass production batch simple production line automatic production line, change the mode of production is also promoted the industrial revolution, not only did he make the efficiency of production, production of quality up upside down, and constantly changed production and enterprise management mode, thus caused the industrial revolution. In fact, in the late 1970 s after automation technology development, the scale of production is more and more big, the technology is more and more complex, technology demand is higher and higher, on the efficiency of production, production of quality people to do the continuously improve and improve. A large - scale, mass - produced model has been basically established. But in today's society is in a period of great changes in the development and adjustment, the uncertainty of social development from the uncertainty of economic development, in order to always stay in that uncertainty of society the sustainable development of enterprises, industries, people use their innovation to create the weapons, with the development of the technology to reduce the uncertainty of economic development. For example, Steve jobs, the computer geek, turned the mainframe into a desktop computer when people were intoxicated with the IBM mainframe computer, and when the desktop became popular, he turned the desktop into a handheld computer. When everyone was typing, he used a touch screen so that even a two-year-old could operate it. Because of these innovative spirit, apple has found a way to develop continuously in an uncertain economic environment. Same if Germany should always maintain its leading position in the field of manufacturing, Germany must also unceasingly to promote the spirit of innovation to promote the continuous development of production machinery manufacturing, since the late 1970 s automatic control system used in the manufacturing system, people also unceasingly to explore how to improve the production efficiency, how to improve the production of products, how to improve the quality of production as well as the flexibility of production, so from the point of view of mechanical manufacturing mechanical and electrical integration of control, management and control integration are put forward. From the perspective of enterprise and production management, MES management and ERP enterprise management are proposed, and digital factories and virtual factories are proposed from the perspective of manufacturing machinery design. In order to improve the flexibility of production, the concept of CIMS was put forward and a lot of experiments and practices were carried out. But there is no solution at the moment we all four major challenges facing the manufacturing industry, namely as the IT technology, the rapid development of PC technology and communication technology puts forward new requirements for manufacturing industry.

It is mainly reflected in the following points:

(1) global production and manufacturing industrial chain;

(2) flexibility in the form of manufacturing;

(3) sustainable development of enterprises;

(4) shortening of the economic development cycle.

Specific speaking, due to the rapid development of science and technology, more and more short product life cycle, rapid response to product upgrading of the demand is higher and higher, because life cycle shorten the product batch is becoming more and more. The reduction in the number of products also raises the cost and price pressure. What's more, the rapidity of the economic cycle requires a shorter investment return time. Meanwhile, energy efficiency, energy conservation and emission reduction are all new challenges we face. How to turn these challenges into new opportunities is the real motivation behind Germany's industry 4.0 strategy. And basic ideas of the industrial strategy of 4.0 is how to make the development of the existing technology through IT with the rapid development of Internet technology to solve the above problem, the combination of 4.0 is industry technical transformation, so the industry is an industry change.

1.3 the strategy of industry 4.0 changes from the transformation of manufacturing industry to the sustainable development of the entire industry in GermanyThe German industry 4.0 strategy is a strategy to maintain its leading position in the global manufacturing equipment sector. IT hopes to start with production machinery manufacturing model reform transition, by using IT technology, Internet technology organically is applied in production in the field of machinery manufacture, to change the basic model of production machinery, in accordance with the flexibility, rapid degeneration, cost efficiency and short-term returns to establish a personalized and highly flexible production mode of digital products and services.

In this model, traditional industry boundaries will disappear and new activities and forms of cooperation will emerge. The process of creating new value is changing, and the division of labor in the industrial chain will be reorganized to make full use of Internet of things technology and equipment monitoring technology to strengthen information management and service. Clearly grasp the production process, improve the production process control, reduce the artificial intervention on production line, real-time production data correctly, and the reasonable production plan and production schedule arrangement. Integrating with emerging technologies such as green, smart, build a high efficiency and energy saving, green environmental protection, the environment comfortable production management control system, its core is to production system and process network distributed manufacturing facilities to achieve; At the same time, enterprise management, including production logistics management, human-computer interaction, and the application of 3 d technology in the product development process, thus forming the integration of new product research and development production management, known as the enterprise life cycle management. Produced a new type of enterprise management manufacturing control service lifecycle management of the industrial chain, the new type of industrial chain to information technology, automation technology, modern management technology, manufacturing technology and new service mode, the combination of cooperation between enterprises, technology communication, new areas, new technology, new ideas, new management mode is bound to attract a large number of medium enterprises to participate in industrial strategy to 4.0, German companies actively involved in the formation and development of a new generation of industrial chain of work, but also attempts to become its results users and beneficiaries.

Actually in Germany in 2009 formulated the "2020" high and new technology, its aim is to lay the German on the key technology of international leading position, and continue to strengthen Germany as the core competitiveness of technical and economic power. Among them, it proposes the following key development areas:

• transportation and logistics

• automotive electronics

• new energy technologies

• energy efficiency

• digital media

• smart buildings

• medical technology

• public safety

Germany in order to realize breakthroughs in the field of the "2020" high and new technology with particular emphasis on promoting interdisciplinary technology: industrial automation technology and microelectronics, the importance of the microprocessor, clearly defines the industrial automation technology is the key to realize the high-tech 2020 Germany, at the same time, in the "2020 white paper" automation and automation is defined as the following

Technology integration:

• electronic and electrical technology

• mechatronics

• production process flow

• computer and IT technology

• sensors and transmitters

• drive and execute systems

• communication technology

High-tech 2020 proposes that the automation control system is a complete solution to process and production process by using and applying automation technology, products and tools. The core of the reform of new production and manufacturing system is to explain the role of automation technology in production and manufacturing. Traditional industrial automation control system is mainly for production must be the information and data transmitted (fieldbus layer), for all the data and information in accordance with the rules made of ideas, people, and will deal with good data and information feedback to the manufacturing execution system or into the upper analysis and decision-making layer (control). Analyze, display, and intervene as necessary for processed information and data or information and data collected directly from the site (offline or online). And the German "automation" 2020 will production process incorporated into category in the field of industrial automation control, as Germany has not clearly put 2020 high and new technology industrial strategy of 4.0 strategy, but in the 2020 high and new technology strategy is very clear points out that the automation technology and the increasingly rapid Internet technology will play a key role to the development of industry. Because this wants to maintain industrial powers, Germany must seize the opportunity, succeeded in automation technology and the rapid development of Internet technology used in industrial applications, in order to impel the strategy of the sustainable development of the industry in Germany.

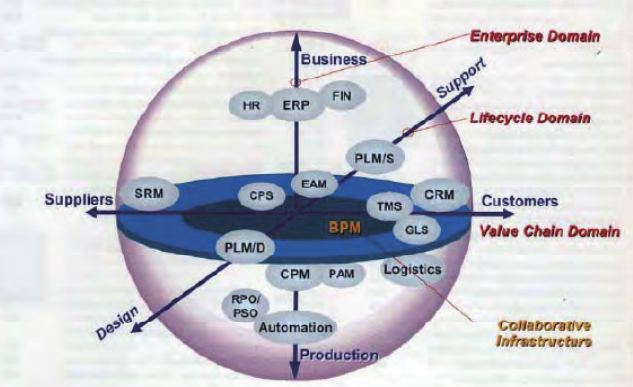

In fact as early as in 2000, according to new development production mode, the international famous consultancy ARC analyzed in detail and current situation of the development of information technology, automation, manufacturing for the trend of the development of science and technology for manufacturing might affect has made a comprehensive investigation, puts forward several leading production automation management mode, to guide the enterprise formulate corresponding solutions, creating higher value for the user. One from production process management, enterprise business management to the research and development of product life cycle management and formation of the "model" of collaborative manufacturing (CollaborativeManufacturingModel CMM). IT will IT technology, industrial and production management technology, network technology and modern automation control network technology is applied to the production control management mode CDAS and CPAS, solve the product life cycle continuously shortening, accelerating logistics delivery cycle and the question of the diversification of customer customization requirements. This CMM collaborative manufacturing model provides an effective method for the reform of the manufacturing industry. Through the research and development process, enterprise management and production industry chain processes organically, form a collaborative manufacturing process, technology and industrial Ethernet communication network at the same time IT as information flow control structure of collaborative manufacturing system, so as to make the MRP, ERP, MES manufacturing management, PLMD/PLMS product development and product service life cycle and the CRM customer relationship management/market organically blend in a complete closed loop system and the market information of enterprise, make enterprise's value chain from a single manufacturing to upstream r&d to design development, production and research and development on the same collaborative platform, Enterprise management chain from upstream to downstream manufacturing control industry chain extension, a set of CRM, PLM, production control and enterprise management, research and development, dacheng collaborative manufacturing management system are forming. The basic core is the so-called enterprise management, production process of value chain and product life cycle triaxial tripartite confrontation pattern of the space, it defines the cooperation among manufacturers, suppliers, and even the developers of the industrial chain of network structure, its key point lies in the cooperative marketing and r&d, cooperative r&d and production, coordination and communication management. A complete manufacturing network consists of multiple manufacturing enterprises or participants that exchange goods and information with each other and jointly execute business processes. The three axes of enterprise, value chain and product life cycle run through the manufacturing participants. Above the water level is the management function and below is the manufacturing function. The CMM model should not only provide solutions for individual departments, but also for the whole enterprise and the entire supply chain after expansion.

Industrial 4.0 successfully apply the idea of CMM, and at the same time according to the characteristics of Germany is now developing manufacturing mode, will be the future project is mainly divided into two main themes, one is "smart factory", focuses on intelligent manufacturing systems and processes, as well as the realization of the network distributed manufacturing facilities; The second is "smart" production, mainly relates to the whole enterprise's production logistics management, human-computer interaction, and 3 d technology application in industrial production process, etc., make use of the Internet of things technology and equipment monitoring technology to strengthen the information management and service; Clearly grasp the production process, improve the production process control, its core is through the use of Internet communication technology and network physical system (Cyber - PhysicalSystem) the means of combining the manufacturing to intelligent transformation. In this way, the research and development of manufacturing technology and the control of all-round information coverage, comprehensive control of all kinds of information, to ensure that all links can be in the optimal state. This reform will guide all walks of life towards the direction of intelligent development of manufacturing industry. IT has promoted the sustainable development of the entire German industry. Robots, complete sets of equipment, IT technology, control technology, information technology and so on will all join in this change. Therefore, the strategy of industry 4.0 aims to transform the manufacturing industry to promote the sustainable development of German industry.